Modern Floor Lamp Prototype Using Poplar and Concrete

Several years ago my wife and I were in the market for a floor lamp. We had a an empty spot between our sofa and chair that needed something…a table…a plant…a floor lamp…something! Ultimately, we decided on a floor lamp AND we decided that I would make it myself. We searched around and saw a lot of desk lamps, floor lamps and pendant lights and I’m sure some of my inspiration and ideas came from seeing some of those, either online or in person.

I always think it’s fun to see the initial sketches and diagrams of finished pieces of furniture and home decor!

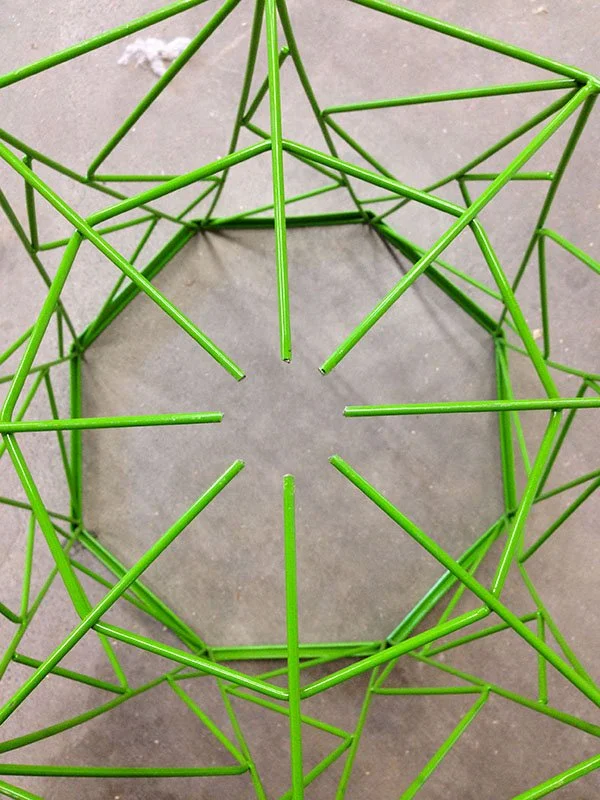

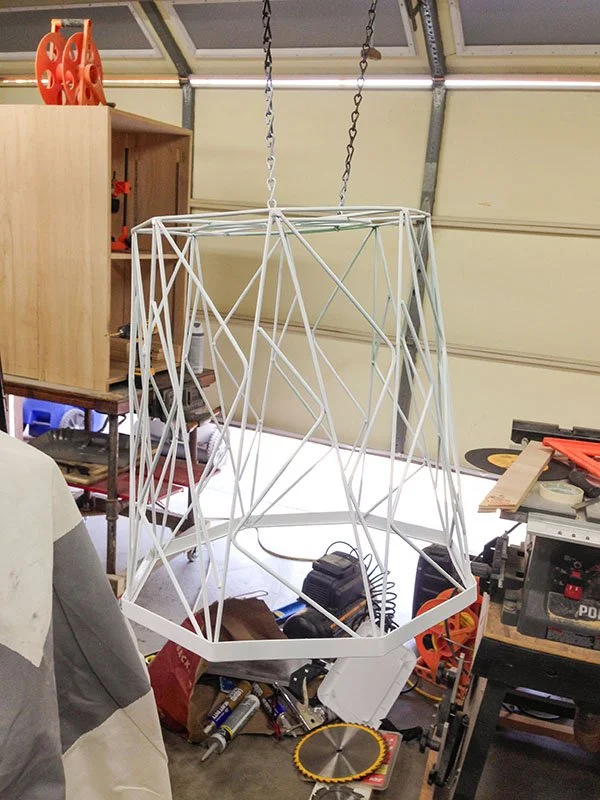

Since this was just something to practice with I decided to use poplar for this project (budget friendly), and I’d make the base out of concrete. The lamp shade is an interesting piece of this puzzle. One day we were walking around Target and saw a bunch of these wire baskets on clearance. They came with a cloth insert, so I think they were just supposed to be storage baskets or maybe waste baskets…who knows, but we immediately thought “lamp shade!”

The wire basket needed a little modification to accept a light socket, so a few snips with the bolt cutter and a little filing down of the sharp edges we got the light socket in place. The original color of the basket was bright green so we also painted it white. We were all set.

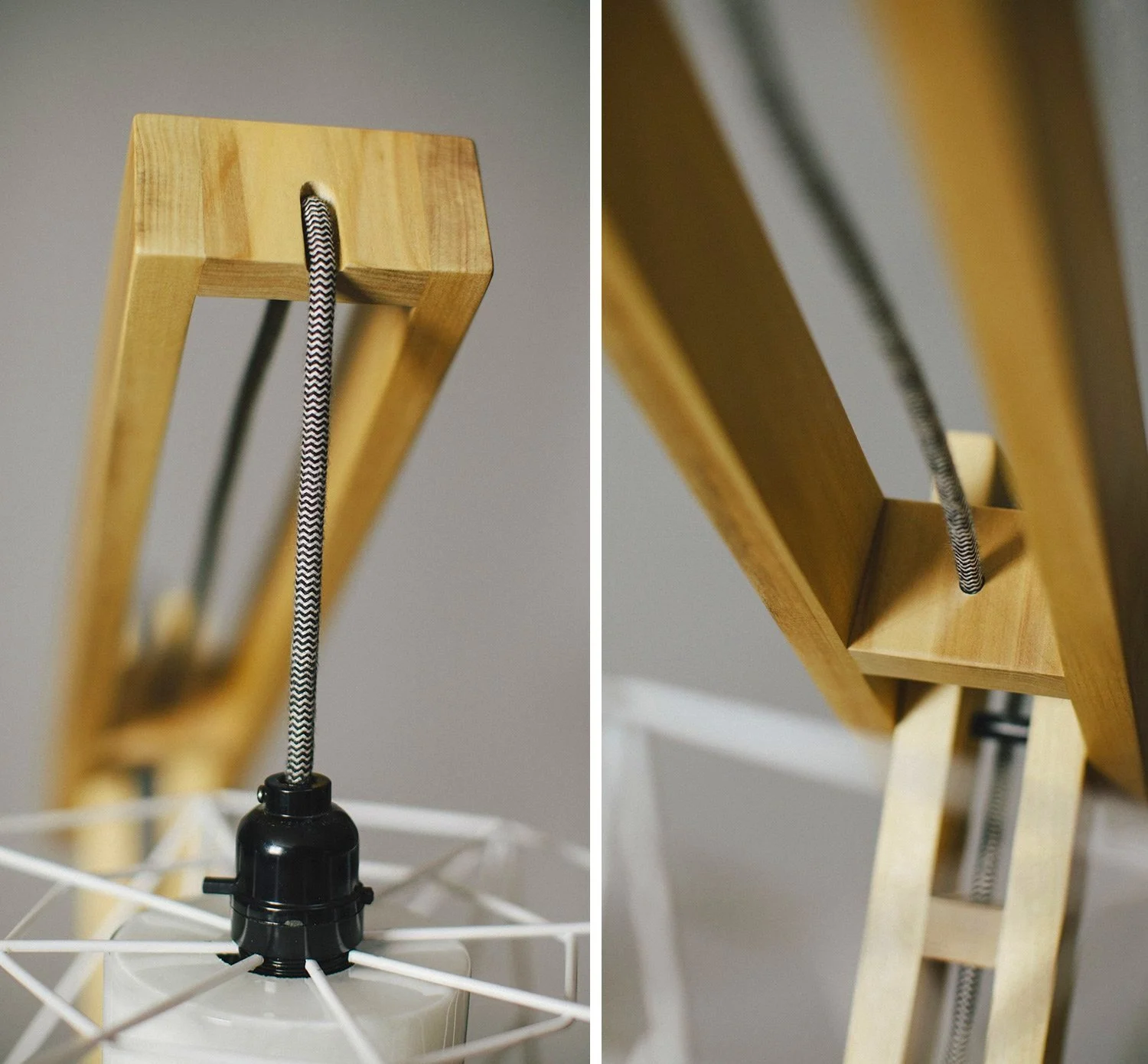

The design and assembly of the poplar body was fairly simple. I bought poplar that was pre-milled to the thickness and width I’d be using, so I didn’t bother with any milling of my own (jointing, planing, etc.) but there was still plenty of sanding to do. I figured out a couple of the angles I wanted and assembled it using Gorilla brand wood glue as well as some allen screw parts for a cleaner, more finished look (as opposed to just using standard nuts and bolts). A forstner bit was used to countersink the allen screws. Man, I love Forstner bits! They’re the perfect bits for so many applications. Finally, the wood got covered with Satin Minwax Water Based Oil-Modified Polyurethane and after a couple rounds of fine sanding and more poly, that gave it a nice smooth finish.

The base was originally going to be a different concrete casting. I had found a large bowl on clearance at Target that had all these geometric angles…it was pretty sweet. But after pouring the concrete and attaching the lamp to it, I didn’t like the size and scale of the base in relation to the rest of the lamp. So I scrapped that one and made a flatter, wider disc-shaped form and poured the concrete into that. Thankfully, concrete is cheap.

Next, I fashioned an anchoring bracket to hold the lamp to the concrete base using a pipe flange, some pipe and a PVC plug (sanded smooth to look more like a nicely finished plug on the pipe). Again, this was just a practice build and at the time I made this, I didn’t have the ability to weld but now I do. If I were making this today there are definitely things I would fabricate differently.

Now I just had to feed the wire through the little holes and attach the socket and plug. This had to be done carefully so I didn’t fray or pull back the chevron zig-zag cloth wrapping on the wire.

The following carousel/slideshow is just a few extra behind-the-scenes images I found in my archives :)

When it was all done I screwed in a light bulb and flipped the switch. After trying several other bulbs first, I landed on a round frosted glass 40-watt LED bulb. The light from the bare bulb was soft enough to tolerate but I still wanted to diffuse it some more. I found a cylindrical glass shade at Lowes that fit inside the wire frame lamp shade and that gave us the diffusion we were looking for.

As I’ve mentioned, this was just a practice project I did several years ago. I would love to revisit the floor lamp idea now that I’ve got more experience with woodworking and welding. I would definitely use a different wood species (probably walnut) and refine the design (I’d probably find a way to incorporate brass too). Since I also have other tools available like a welder, cnc machine, a Creality Falcon2 Pro laser engraver/cutter and a Prusa 3D printer, I think the sky’s the limit. What do you think?

Have you ever made a lamp? Have you ever upcycled an unconventional item and used it for something other than what it was intended for? Tell me about it by leaving a comment. I’d love to hear about your experience. Thanks for stopping by the blog of Seth Mondragon - American Craftsman.

I use Amazon Affiliate links in my blog posts. When you click the links and purchase various items on Amazon, I may earn a small commission from qualifying purchases which I can then use towards my webhosting costs. Thank you for your support!